We are Brightech

Brightech®

was established in 2000

Equipped with nothing but knowledge, Brightech® began its journey in 2000, with a desire to make a difference in the spectrum of fluid control systems.

Faced with the daunting challenge of establishing its name in a monopolised marked, Brightech utilised constant innovation and product development to turn the wheels in its favour.

Contact Us

As your Industrial Instrumentation Valves supplier, it’s our responsibility to bring increased value to your company.

Get in touch with us

| M: | 9909029165, 9725455442 |

| E: | info@brightechvalves.com |

| M: | 7069004459 |

| E: | exports@brightechvalves.com |

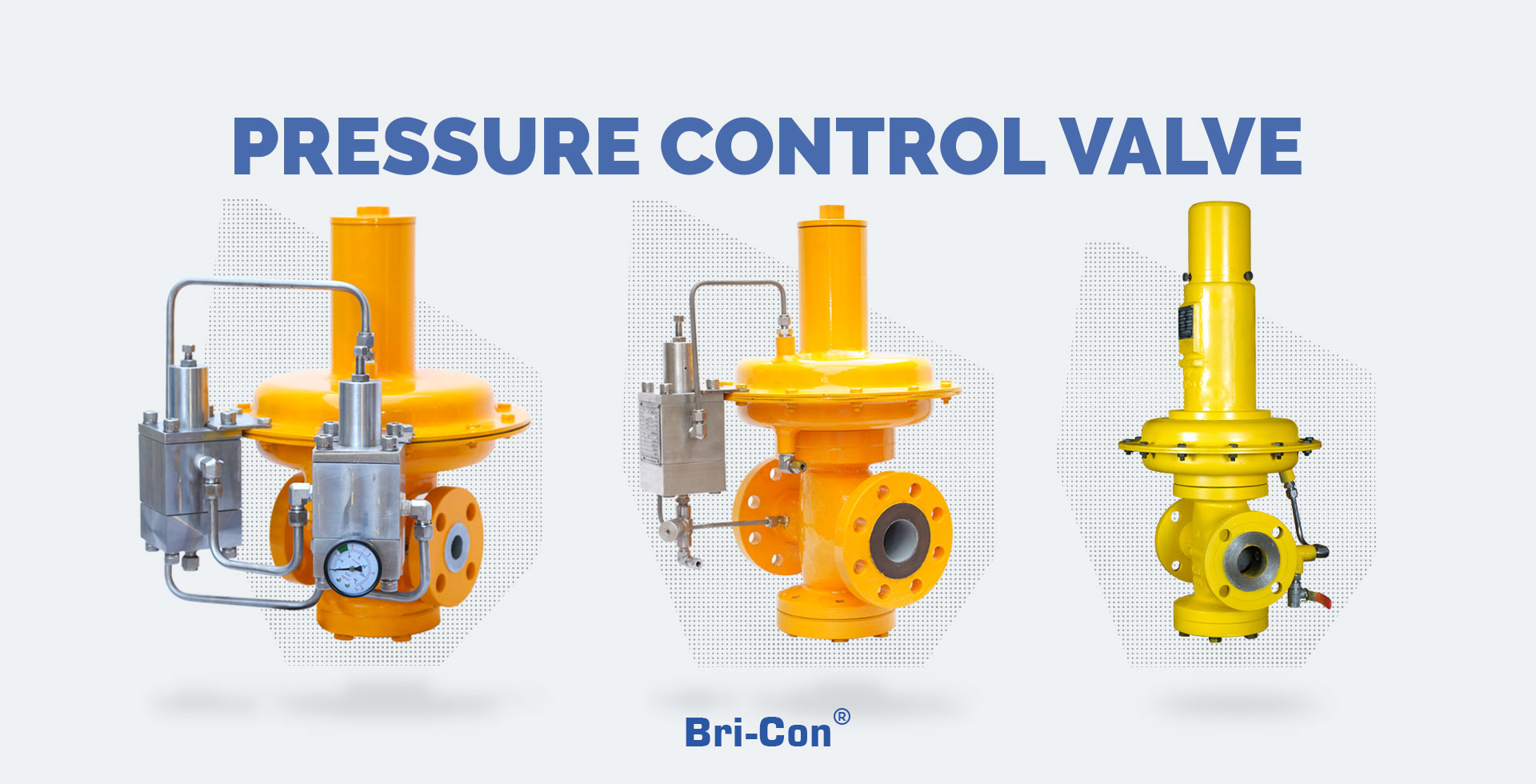

Products

Premier supplier

you can trust

Brightech® is a pioneer Instrumentation Valves Manufacturer in India.

We provide Safety Relief Valve, Pressure Reducing Valve, Pressure Reducing & Desuperheating Station, Pressure Control Valves, Industrial Gas Regulator, Pneumatic / Motorized Control Valve, Automatic Control Valves that are manufactured to the most stringent industry standards. widely applied in the field of a various kinds of industries.To provide safe and reliable products and complete solutions for clients in fluid conveying industry across the global.

Our

Applications

Quality

Standard & Approvals